Author: Dr James Edmondson, Research Director at IDTechEx

Electric vehicles (EVs) are a key route to decarbonizing the transport sector. However, the materials that are used within them often come under scrutiny regarding their sustainability. Objectively quantifying sustainability is very difficult due to its dependence on multiple factors, but certain technologies, materials, and practices can certainly be more or less sustainable than others. As a key part of an EV’s drivetrain, considering the sustainability of electric motor designs is also important when looking at the sustainable nature of a vehicle. IDTechEx’s report, “Electric Motors for Electric Vehicles 2025-2035: Technologies, Materials, Markets, and Forecasts”, predicts the need for over 160 million electric motors per year by 2035. This article aims to discuss some of the key factors and tradeoffs to be made for electric motor design if sustainability is the ultimate goal.

The impact of material choice

In the vast majority of cases, the materials used in the stator of electric motors in the EV market are very similar, with steel laminates and copper windings. The major difference comes down to the rotor materials. Rare earth permanent magnet motors make up the majority of the market, with IDTechEx finding they had an 85% market share in electric cars for 2023.

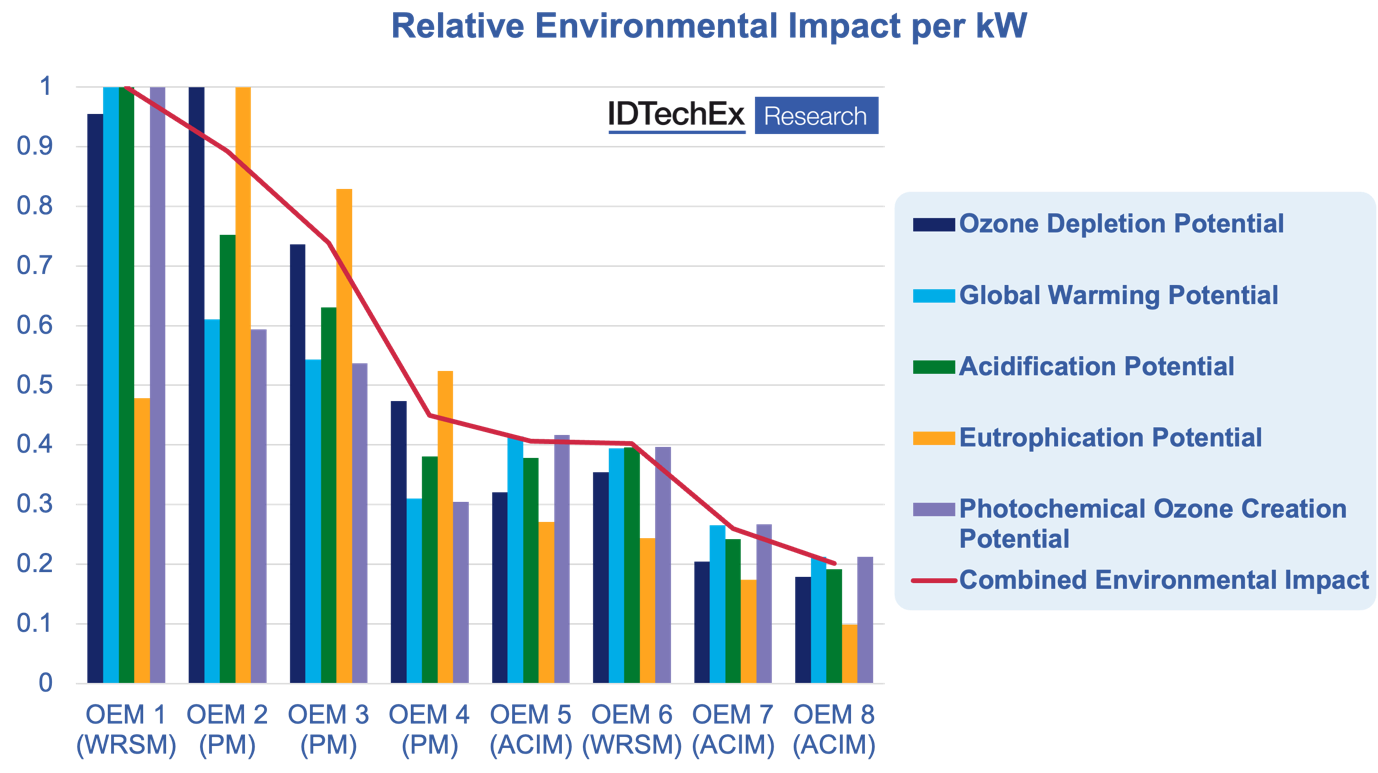

Of the materials considered for electric motors (steel, aluminum, copper), per kg, rare earths have the largest environmental impact when considering the potential for ozone depletion, global warming, acidification, eutrophication, and photochemical ozone creation. While they are a relatively small amount of the motor (less than 1-2kg), rare earth-containing motors tend to have a larger impact on the environment per kW of power compared to the rare earth-free alternatives, despite the fact magnet-free motors typically require greater amounts of other materials like copper. However, magnet free motors may require other manufacturing steps that could increase energy consumption in manufacturing.

IDTechEx analysis of the environmental impact of materials in various commercial EV motors. Source: IDTechEx

Increasing power density and efficiency to improve sustainability

Simply put, a more efficient motor means less energy is wasted driving the vehicle. This means less electricity from the grid being used, which, depending on the grid, could be significant in reducing CO2 output. Additionally, a more efficient motor means a smaller battery could be used to achieve the same vehicle range, therefore reducing material use and the environmental impact of the battery system.

The other aspect is power density. A more power-dense motor will use less materials to achieve the same power output. Taking an extreme example of high power density with an axial flux motor, players interviewed by IDTechEx have claimed a power of 190kW can be achieved with less than 1.2kg of magnets or ~6.3 grams/kW. Compare this to a typical modern radial flux motor at around 10 grams/kW.

Do we need more motors?

IDTechEx’s research has found that the average number of motors used per BEV in 2023 was 13% higher than in 2015, as more vehicles are deployed with dual, tri, and quad motor variants. Of course, having more motors in a vehicle will increase material utilization, not just for the motor but also for all of the associated electronics and thermal management components.

One could ask the question: how many consumers actually need more than one motor? It is certainly a nice luxury to have, and automakers often prefer selling these higher-specification vehicles that command a higher profit margin. This does reduce the sustainability of the vehicle; however, if it means more people are willing to purchase a BEV, then this can be seen as a step in the right direction for the environment in general. IDTechEx believes that a key step for reinvigorating growth in the EV market will be the availability of low-cost models (especially in Europe) that will likely command a single-motor solution to keep costs down.

How large a factor is sustainability?

Sustainability is a core goal of most modern businesses, with many having net-zero goals in the not-too-distant future and entire departments dedicated to reducing the company’s environmental impact. As automakers try to make more profitable EVs, which will be a large factor in the decarbonization of road transport, the sustainability of EV components will often fall behind factors such as performance, efficiency, and price. Additionally, more scrutiny is often given to the battery materials, and rightly so, given the quantities used in comparison to the motors. This is reflected in early regulations like the battery passport in Europe that requires the CO2 footprint of the battery to be reported. The majority of the initial sustainability focus will be in this area, but in the future, the motor could prove a significant route to improving vehicle sustainability.

IDTechEx’s report, “Electric Motors for Electric Vehicles 2025-2035: Technologies, Materials, Markets, and Forecasts”, analyses the current technology and materials landscape for electric motors in EVs and forecasts the future trends and demands for the next 10 years. IDTechEx forecasts that over 160 million electric motors will be required for the EV market in 2035, with approximately 30% of the automotive market using rare earth-free technologies in the same year.

To find out more about this report, including downloadable sample pages, please visit www.IDTechEx.com/Motors.

For the full portfolio of electric vehicle market research available from IDTechEx, please see www.IDTechEx.com/Research/EV.