Author: Dr Shababa Selim, Technology Analyst at IDTechEx

Two years after signing the US Chips Act into law for onshore chip manufacturing, over US$30 billion of the total US$39 billion in direct incentives have been awarded to date. With the remainder set for allocation by the end of the year, the US Chips Act is progressing steadily. Given helium’s critical role in semiconductor production, onshoring chip manufacturing will have a significant knock-on impact on the helium demand for semiconductor manufacturing. According to IDTechEx forecasts in its report on the topic, “Helium Market 2025-2035: Applications, Alternatives, and Reclamation”, helium demand for chip manufacturing will nearly quadruple in the US by 2035.

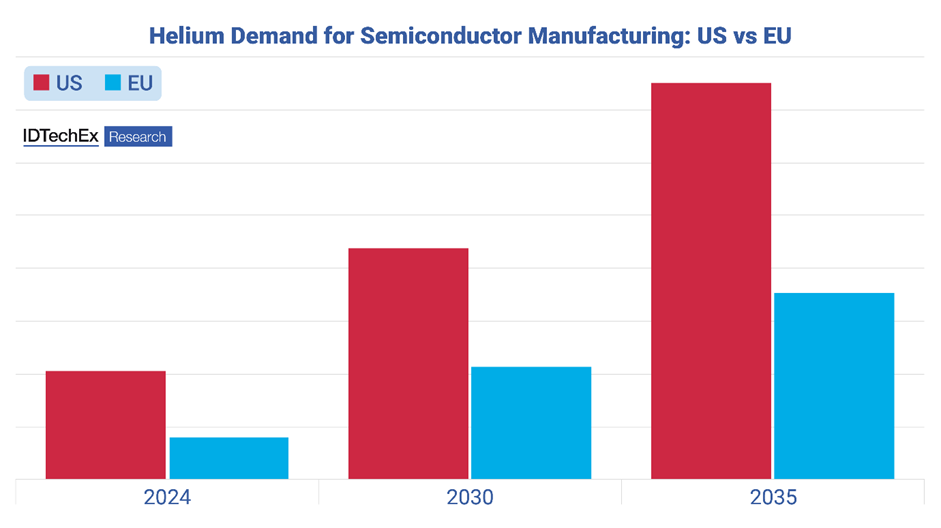

US Chips Act and EU Chips Act set to grow demand for helium. Source: IDTechEx

AI driving demand for semiconductors

Following the US Chips Act, several players have announced investments to expand production capacity in the US, particularly to manufacture advanced node technologies. Demand from AI, quantum computing, telecoms (e.g., 5G and beyond), electric vehicles, etc., is projected to be significant drivers of growth in semiconductor manufacturing and, hence, helium use. Helium’s exceptionally high thermal conductivity and chemically inert nature allow the fast cooling of chips during production. With no other viable alternative to helium, IDTechEx predicts the global helium demand for semiconductor manufacturing to increase by over 5-fold by 2035, with the US alone expected to see the demand quadruple over the next decade.

Progress in EU and US chips acts

With over US$395 billion in announced investment from multiple companies in semiconductors and electronics, significant onshoring of semiconductor production is expected in the US over the next decade. For example, Intel plans to invest over US$100 billion over 5 years to expand its chip-making capacity in the US, with facilities across Arizona, New Mexico, Oregon, and Ohio. Similarly, TSMC is constructing three fabs across Arizona, with the first fab expected to begin the production of 4nm process technology in H1 of 2025, while more advanced nodes (e.g., 2nm and 3nm process technologies) are expected to be in production towards the end of the decade. Similar to the US Chips Act, the EU Chips Act allocates US$47 billion in investment to onshore semiconductor manufacturing capabilities within the EU. This has incentivized the likes of Intel, TSMC, STMicro, Global Foundries, and others to invest in new semiconductor fabs in Europe.

Onshoring chip production can add strain on existing supply chains

Onshoring to boost regional growth of semiconductor production across the EU and the US will undoubtedly lead to a substantial increase in the demand for raw materials and gases, such as helium, that are used during the manufacturing process. Therefore, supply chains will need to be robust and grow in line with chip manufacturing capacity. This is particularly critical for helium, a finite resource that experiences chronic supply challenges and market volatility.

Although helium production capacity is anticipated to increase, with Qatar and Russia expected to ramp up production, it does not necessarily guarantee a disruption-free helium supply moving forward when considering geopolitical tensions in regions where helium is largely produced. The semiconductor industry will increasingly need to consider helium management solutions such as helium recycling and reclamation technologies to future-proof the industry's sustainable growth.

IDTechEx outlook

The future of supply security of helium is a major concern in the specialty gas market and for industries that are critically reliant on the gas. With several initiatives from the US, EU, and China to onshore and expand semiconductor production, IDTechEx forecasts the global helium demand for semiconductor manufacturing will increase by over 5-fold by 2035. In light of the EU and US Chips Acts, IDTechEx predicts that both the EU and the US will see the helium demand from the semiconductor industry quadruple over the next decade. To meet the requirements of the growing semiconductor and electronics industry, materials and specialty gas companies will need to establish supply security with robust supply chains.

IDTechEx’s report, “Helium Market 2025-2035: Applications, Alternatives, and Reclamation”, provides key market insights into the production and supply of helium, the major applications, outlook, and trends in how industries are adapting to cope with chronic supply challenges with helium conservation methods (e.g., reclamation technologies) or adopting substitutes where possible.

To find out more about this report, including downloadable sample pages, please see www.IDTechEx.com/Helium.

For the full portfolio of advanced materials market research available from IDTechEx, please visit https://www.IDTechEx.com/Research/AM.